| Water Ring Vacuum Pump |

|

| Product Specification |

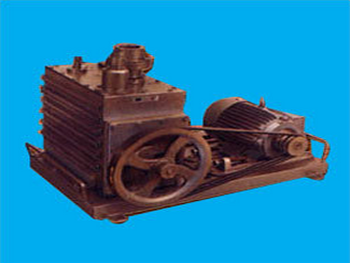

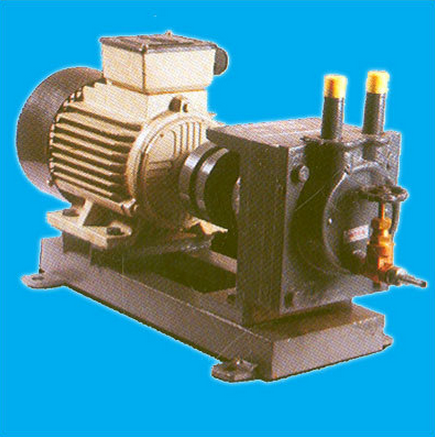

Water Ring Vacuum Pump

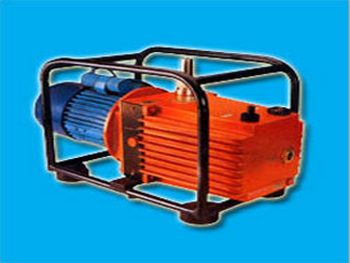

Double Stage Water Ring Vacuum Pump

The liquid Ring Vacuum Pump is of a technology based on the requirement of its usefulness for Handling Moist Air Gases & vapours of Toxic nature.

Applications

- For priming Pumps and Syphons

- Evaporation

- Condensation

- Pharmaceutical & Chemical Industries

- Food Stuffs Manufacturing

- Textile Mills

- Paper Mills

- Solvent Extrusion Plant

- Confectioneries etc.

In normal installation where water is used as liquid ring and cooling fluid, the exhaust & cooling fluid are delivered together into the drains. A silencer is fitted to the exhaust pipe to minimize the noise. A non-return valve is also provided to the suction side to check the water flow into the vacuum line

in case of operational failure. A vacuum relief valve to limit the vacuum pressure, can be supplied on request. Basically the temperature and evaporation properties of the ring fluid will determine the ultimate vacuum of the pump.

Installation as a compressor

For its use as a compressor, a water separator is provided at the exhaust side for separation of ring water to drain which can be re-circulated. In water ring compressor a non return valve is fitted to the exhaust side. A safety valve can be provided to the exhaust side to limit the working pressure.

Models Specifications

Model LRV |

Speed RPM |

Suction C.F.M |

Suction m3/hr |

Recommended H.P |

Sealing water consumption L.P.M |

Approx wt. Bare pump kg. |

Suction exhaust size |

LRV-001 |

2850 |

12 |

20 |

1 |

1.5 |

17 |

15x15 |

LRV-002 |

2850 |

18 |

30 |

2 |

2 |

22 |

15x15 |

LRV-1 |

2850 |

30 |

50 |

3 |

4 |

38 |

25x25 |

LRV-2 |

2850 |

50 |

85 |

5 |

9 |

46 |

31x31 |

LRV-3 |

2850 |

75 |

128 |

7.5 |

13 |

51 |

38x38 |

LRV-4 |

1440 |

100 |

170 |

7.5 |

16 |

175 |

50x50 |

LRV-5 |

1440 |

130 |

220 |

10 |

20 |

190 |

50x50 |

LRV-6 |

1440 |

200 |

340 |

16 |

28 |

225 |

50x50 |

LRV-7 |

1440 |

260 |

440 |

20 |

40 |

250 |

75x75 |

Model |

700 |

600 |

400 |

200 |

100 |

0 |

Mm of hg |

LRV-001 |

0 |

2.8 |

8.2 |

14..5 |

18.4 |

20.1 |

M3/hr. |

LRV-002 |

0 |

3.1 |

11.3 |

18.5 |

24.6 |

30.4 |

M3/hr. |

Product Code : 03 |